Which Type of Transducer?

Transom Mount:

Transom mounted transducers are attached to the transom at the stern of the vessel. Trailered vessels typically use this mounting style. A transom-mounted installation usually gives good readings up to 25-30 knots depending on installation.

Transom mounts are usually plastic and tend to be less expensive than other transducers. Fish finders and chart plotters/fish finders often come bundled with a transom mount transducer - this is usually the least expensive way to buy your system.

Transom mount transducers are recommended for planing hulls of less than 27 feet (8 meters), such as personal watercraft and powerboats with outboard, stern drive and jet drives. They are not recommended for large or twin screw inboard boats because aerated water from the propeller reduces performance. They are also not recommended for operation at very high speeds.

- Choose a location where the water flow is the smoothest, with minimum turbulence and bubbles, especially at high speed.

- The transducer requires continuous contact in water and the sounder beam unobstructed by the keel or propeller shaft.

- Make sure that a location with minimum deadrise angle is chosen.

- Look for features on the hull like lifting strakes or keels in front of the proposed transducer location. These structures will cause cavitation and will negatively affect performance. A disadvantage of a transom mount is that at high speed. air bubbles can affect the sonar performance.

- The location should be as close to the centre of the boat as practical, and on the side prop wash. On most engines, this will be on the starboard (right) side; because the propeller rotates clockwise when viewed from the stern.

- On boats with outboard motors or stern drives, the location should be at least 15 inches (38 cm) away from the propeller.

- The location should not be immediately in front of the propeller on single-drive boats. The transducer can cause cavitation that can degrade the performance of the boat and damage the propeller.

- The location should not be downstream of any strakes, struts, fittings, water intake or discharge ports, or anything that creates air bubbles or causes the water to become turbulent.

- On twin-drive boats, the location should be between the drives, if possible.

- Avoid locations where physical jarring of the transducer could occur. Consider the position of the transducer when launching, hauling, or storing.

- The transducer should be oriented so that it is parallel with the waterline.

- When installing a transom-mounted transducer, it is crucial that you carefully follow the installation instructions provided within each transducer kit. The following are basic guidelines to consider when mounting this type of transducer:

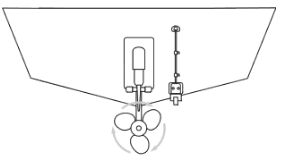

The below images are sample installations and do not apply to every boat:

Through Hull

Through-hull transducers are just that; a hole through the hull of the boat with the transducer installed through the hole. Thru-hull transducers come in two versions, tilted element or with a fairing block. If the tilted element is insufficient for the deadrise, choose a transducer with a larger tilt angle. If the deadrise is too great for a fairing block installation, then a pair of through hulls will be required. There are specific placement locations based on the type of hull and type of engine on the vessel. Be sure to read through the manufacturers mounting considerations before drilling a hole.

Below are some general guidelines for placement. Because of the complexity of through-hull installations, we recommend a professional installer for this type of transducer installation.

- On outboard and stern drive vessels the transducer should be mounted in front of and close to the engine or engines.

- On inboard vessels the transducer should be mounted in front of and far away from the engine propeller and shaft.

- On step-hull vessels the transducer should be mounted in front of the first step.

- On full-keel vessels the transducer should be mounted at a slight angle that aims at the bow, not parallel to the centreline.

- On fin-keel vessels the transducer should be mounted 10 – 30 inches (25 cm – 75 cm) in front of the keel and a maximum of 4 inches (10 cm) to the side of the centreline.

- On displacement hulls the transducer should be mounted approximately 1/3 aft of the waterline length of the vessel from the bow, and 6 – 12 inches (150 – 300 mm) to the side of the centreline.

- The transducer should be mounted parallel to the bow-stern axis of your vessel.

- Do not mount the transducer behind strakes, struts, fittings, water intake or discharge ports, or anything that creates air bubbles or causes the water to become turbulent.

- The transducer must be in clean, flowing water (non-turbulent) water for optimal performance.

- The transducer location should not cause jarring when launching, hauling, or storing.

- On single-drive vessels the transducer must not be mounted in the path of the propeller. The transducer can cause cavitation that can degrade the performance of the boat and damage the propeller.

- On twin-drive vessels the transducer should be mounted between the drives, if possible.

SideVu/3D/ClearVu/HyperVision/RealVision/DownScan/StructureScan Imaging:

These transducers may need to be installed as a pair. In this instance, a Y-split cable connects the pair of transducers together and then a single cable is plugged into the chartplotter. A pair of transducers is required if the deadrise is too great or there is no flat area of sufficient size on the bottom of the boat. As below:

In Hull

An in-hull transducer installation is bonded to the inside of the hull with epoxy and will typically consist of a container filled with propylene glycol. When installing an in-hull mounted transducer, it is essential that you carefully follow the installation instructions provided within each transducer kit. The following are basic guidelines to consider when mounting this type of transducer:

In-Hull Pros and Cons

Pros:

- No need to drill through the vessel; no drag

- Trailering the boat without causing damage to the transducer

- Can be installed and serviced with the vessel in the water

- Excellent high-speed performance if water flow below the sensor is free-flowing (no turbulence)

- Works with any engine type: inboard, outboard, and stern drive when installed over solid fiberglass

- Performs well on both power and sailboats

Cons:

- Not recommended for metal, wood or cored fiberglass hulls, where a hard insert would be required

- Loss of signal by transmitting through-hull. The signal will pass through up to 0.75” thickness

- Avoid mounting too close to the keel; cone signal shape is approximately 22 degrees. If too close to the keel, it can pick up an echo.

- Should be in the aft part of the boat

- Test the location - use a thin plastic bag filled with water, place the transducer inside the bag, and close with a zip tie. Use water to wet the desired hull location. Plug in transducer and check the chart plotter's sonar page - are good returns shown?

- Periodically check the tank and fill when needed with propylene glycol. Flashing depth or no depth information indicates that there is not enough fluid or no fluid in the reservoir.